Excellent high-frequency electrical properties. Glass is an insulating material with a dielectric constant that is only about one-third of that of silicon, and its loss factor is 2-3 orders of magnitude lower than that of silicon, which significantly reduces substrate loss and parasitic effects, ensuring the integrity of the transmitted signal.

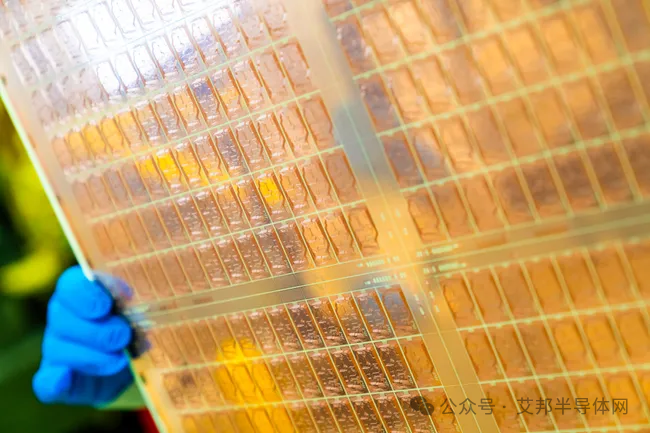

Large-size ultra-thin glass substrates are readily available. Glass manufacturers such as Corning, Asahi, and SCHOTT can provide extra-large size (>2m x 2m) and ultra-thin (<50µm) panel glass, as well as ultra-thin flexible glass materials.

Low cost. Benefiting from the easy availability of large-size ultra-thin panel glass and the elimination of the need for depositing an insulating layer, the manufacturing cost of glass interposers is about only one-eighth that of silicon-based interposers.

Simplified manufacturing process. There is no need to deposit insulating layers on the substrate surface or on the inner walls of Through-Glass Vias (TGVs), and thinning of the ultra-thin interposer is not required.

Strong mechanical stability. Even when the thickness of the interposer is less than 100µm, warping remains minimal.

Wide application range. This is an emerging vertical interconnect technology used in the field of wafer-level packaging. It offers a novel technical approach for achieving the shortest possible distances and minimal spacing between chips, providing excellent electrical, thermal, and mechanical properties. This technology has unique advantages in fields such as RF chips, high-end MEMS sensors, and high-density system integration. It is considered one of the preferred options for the next-generation 3D packaging of 5G and 6G high-frequency chips.

Organizers: Shenzhen Ebang Intelligent Manufacturing Information Co., Ltd., Ebang Semiconductor Network

| 序号 | Topic | Companies to be invited |

| 1 | Challenges and solutions of TGV glass core technology | Guangdong Fozhixin Microelectronics Technology Research Co., LTD |

| 2 | Difficulties in the production of TGV metal lines and their technical solutions | Hubei TGVTECH Co., Ltd. |

| 3 | Glass core substrate: a new generation of advanced packaging technology | AKM Meadville Electronics (Xiamen) Co. Ltd. |

| 4 | The latest generation of TGV technology and applications | 3D CHIPS (GUANGDONG) TECHNOLOGYCO.,LTD |

| 5 | SCHOTT glass enables advanced packaging | SCHOTT Group |

| 6 | Application of microscope in semiconductor advanced packaging defect detection | Guangdong Huipuguangxue Technology Co., Ltd. |

| 7 | Prospects for the application of through-glass technology in advanced packaging | Xiamen Sky Semiconductor Technology Co.Ltd. |

| 8 | Discussion on the filling technology of through-hole in glass substrate | Guangdong Tiancheng Technology Co., Ltd. |

| 9 | Laser-induced deep etching technology is used to realize the processing of glass substrates with integrated multi-functional structures | LPKF China |

| 10 | Design, development and application of high-performance IPD based on TGV | ShangHai Xpeedic Co., Ltd. |

| 11 | Application of Multi-physics Simulation Technology in Glass-based Advanced Packaging | Hunan More Than Moore Advanced Semiconductor Co.,Ltd. |

| 12 | High-density glass-level packaging and heterogeneous integration process development challenges and solutions | Chengdu ECHINT Technology Co., Ltd. |

| 13 | Application of PVD equipment in deep hole coating in TGV technology | Guangdong Huicheng Vacuum Technology Co., Ltd. |

| 14 | From round to square: Evatec's advanced packaging substrate FOPLP etching and sputtering solutions | Evatec China |

| 15 | The latest progress and future prospects of glass substrate packaging technology | Shenzhen Fanxin Integrated Semiconductor Co., Ltd. |

| 16 | Innovative technologies and applications of glass substrates: from plasma vias to surface modification and metal seed layer technology | UVAT Technology co.,Ltd. |

| 17 | Panel level laser induced etching & AOI | Shenzhen GH LASER Co., Ltd. |

| 18 | Integrated passive on glass substrate | SUzhou senwan Electronic Technology Co., Ltd. |

| 19 | 玻璃基板量产线 铜线路蚀刻工艺 | 广州市巨龙印制板设备有限公司 |

| 20 | 用于TGV封装领域的光学量检测技术 | 北京电子量检测装备有限责任公司 |

拟邀请玻璃衬底企业,玻璃基板,TGV加工,芯片设计,封装企业,设备企业如:激光设备,蚀刻设备,镀膜设备,等离子设备,电镀设备,CMP设备,检测设备,RDL设备,材料企业如:蚀刻液,电镀药水,抛光耗材,靶材,临时键合胶,光刻胶,显影液,清洗液等等。

|

京东方 |

北京赛微电子股份有限公司 |

|

SUzhou senwan Electronic Technology Co., Ltd. |

苏州甫一电子科技有限公司 |

|

海太 |

苏州晶方半导体科技股份有限公司 |

|

合肥三芯微电半导体有限公司 |

长鑫存储 |

|

合肥中科岛晶科技有限公司 |

沃格光电 |

|

Hubei TGVTECH Co., Ltd. |

湖北五方光电股份有限公司 |

|

蓝思科技 |

广州增芯科技有限公司 |

|

Hunan More Than Moore Advanced Semiconductor Co.,Ltd. |

广东越海集成 |

|

浙江蓝特光学股份有限公司 |

绍兴同芯成集成电路有限公司 |

|

Chengdu ECHINT Technology Co., Ltd. |

玻芯成(重庆)半导体科技有限公司 |

|

华润微 |

奥特斯(中国)有限公司 |

|

江西红板科技股份有限公司 |

江西红森科技有限公司 |

|

Guangdong Fozhixin Microelectronics Technology Research Co., LTD |

3D CHIPS (GUANGDONG) TECHNOLOGYCO.,LTD |

|

深圳市兴森快捷电路科技股份有限公司 |

深圳莱宝高科技股份有限公司 |

|

广州广芯封装基板有限公司 |

深南电路 |

|

珠海昊玻光电科技有限公司 |

深圳雷曼光电科技股份有限公司 |

|

广西珍志新材料有限公司 |

广西华芯振邦半导体有限公司 |

|

Xiamen Sky Semiconductor Technology Co.Ltd. |

AKM Meadville Electronics (Xiamen) Co. Ltd. |

|

宸鸿科技(厦门)有限公司 |

渠梁电子有限公司 |

|

鈦昇科技 |

群翊工业股份有限公司 |

|

三德科技有限公司 |

华进半导体封装先导技术研发中心有限公司 |

|

中科院合肥研究院 |

中科院微电子所 |

|

中国科学院合肥物质院智能所 |

厦门大学 |

|

中国电子科技集团公司第十四研究所 |

LG Innotek |

|

LX Semicon |

SK Nexilis |

|

SKC |

Samtec |

|

Absolics |

大日本印刷株式会社(DNP) |

|

株式会社NSC |

Nanosystems JP Inc. |

|

TECNISCO |

日本Kiso Wave |

|

Plan Optik |

通富微电子股份有限公司 |

|

江苏长电科技股份有限公司 |

江苏中科智芯集成科技有限公司 |

|

长沙安牧泉智能科技有限公司 |

深圳市深光谷科技有限公司 |

|

Hangzhou MDK Opto Electronics Co., Ltd |

海力士 |

|

英特尔 |

英伟达 |

|

AMD |

华为 |

|

三星 |

LG |

|

德国乐普科LPKF |

德国4JET |

|

韩国Philoptics |

广东大族半导体装备科技有限公司 |

|

武汉帝尔激光科技股份有限公司 |

钛昇科技股份有限公司 |

|

苏州德龙激光股份有限公司 |

武汉华工激光工程有限责任公司 |

|

深圳市圭华智能科技有限公司 |

迈科微纳半导体技术(昆山)有限公司 |

|

武汉华日精密激光股份有限公司 |

成都莱普科技股份有限公司 |

|

深圳市韵腾激光科技有限公司 |

杭州银湖激光科技有限公司 |

|

海目星激光科技集团股份有限公司 |

创轩激光 |

|

首镭激光 |

EKSPLA |

|

TRUMPF |

武汉华日精密激光股份有限公司 |

|

苏州贝林激光有限公司 |

RENA |

|

美国YES |

Ekspla |

|

Han's Laser Technology Industry Group Co., Ltd |

深圳市圭华智能科技有限公司 |

|

广州市巨龙印制板设备有限公司 |

深圳正阳工业清洗设备有限公司 |

|

东台精机 |

苏州尊恒半导体科技有限公司 |

|

武汉精测电子集团股份有限公司 |

三姆森 |

|

台湾欧美科技OmniMeasure |

台湾东捷科技 |

|

苏州佳智彩光电科技有限公司 |

北京电子量检测装备有限责任公司 |

|

Evatec AG. |

UVAT Technology co.,Ltd. |

|

台湾富临科技 |

北方华创 |

|

Guangdong Huicheng Vacuum Technology Co., Ltd. |

深圳市矩阵多元科技有限公司 |

|

光驰科技(上海)有限公司 |

LAM RESEARCH |

|

日本KOTO江东电气集团 |

盛美半导体设备(上海)股份有限公司 |

|

Manz亚智科技 |

海世高半导体科技(苏州)有限公司 |

|

东威科技 |

吉姆西半导体科技(无锡)股份有限公司 |

|

鑫巨(深圳)半导体科技有限公司 |

深圳正阳工业清洗设备有限公司 |

|

广州明毅电子机械有限公司 |

深圳市荣华安骏机电设备有限公司 |

|

苏科斯(江苏)半导体设备科技有限公司 |

北京特思迪半导体设备有限公司 |

|

合美半导体(北京)有限公司 |

华海清科股份有限公司 |

|

深圳市梦启半导体装备有限公司 |

江苏正钜智能装备有限公司 |

|

浙江大江半导体科技有限公司 |

浙江厚积科技有限公司 |

|

苏州博宏源设备股份有限公司 |

光力瑞弘电子科技有限公司 |

|

成都莱普科技股份有限公司 |

康宁 |

|

日本旭硝子 |

JNTC |

|

肖特 |

日本电气硝子NEG |

|

Mosaic Microsystems |

中建材 |

|

彩虹集团有限公司 |

东旭光电科技股份有限公司 |

|

旭化成 |

赛德半导体 |

|

上海沪源达光电有限公司 |

江苏艾森半导体材料股份有限公司 |

|

山之风 |

深圳市合明科技有限公司 |

|

晶呈科技股份有限公司 |

广东欧莱高新材料股份有限公司 |

|

韩国YCchem |

安美特 |

|

奥野制药工业株式会社 |

上海新阳半导体材料股份有限公司 |

|

广东天承科技股份有限公司 |

深圳创智芯联科技股份有限公司 |

|

广州三孚新材料科技股份有限公司 |

深圳市百柔新材料技术有限公司 |

|

苏州锦艺新材料科技股份有限公司 |

长沙光祺电子科技有限公司 |

| 付款时间 | 1-2人 | 3人及以上 |

| 2025年1月18日前 | 2700/人 | 2600/人 |

| 2025年3月18日前 | 2800/人 | 2700/人 |

| 现场付款 | 3000/人 | 2800/人 |

★费用包括会议门票、全套会议资料、午餐、茶歇,晚宴等,但不包括住宿;

李小姐:18823755657(同微信)

或者复制网址到浏览器后,微信注册报名

https://www.aibang360.com/m/100235?ref=100042

原文始发于微信公众号(艾邦半导体网):2025年玻璃基板TGV产业链高峰论坛(2025年3月,苏州)